To ensure that our manufactured cables meet the highest standards of safety, reliability and durability,…

Cable testing laboratories and quality management

At Top Cable we have cable testing laboratories that allow us to ensure that all cables manufactured in our factories are subject to strict quality controls and undergo numerous rigorous testing processes to verify. We know our cables and can guarantee the electrical and environmental performance you need in your industrial installations.

ADDED VALUE OF CABLE TESTING LABORATORIES

The tests we can perform in our cable testing laboratories allow us to analyse every single cable we obtain in our production process. In doing so, we can analyse three key aspects of our cables:

- Cable quality: evaluating the materials and construction.

- Cable functionality: testing their electrical and operational performance.

- Cable conformity: ensuring cables meet specific standards.

Our extensive cable testing laboratories are equipped with the latest state-of-the-art technology and have the capacity to carry out the most demanding tests on the cables we manufacture.

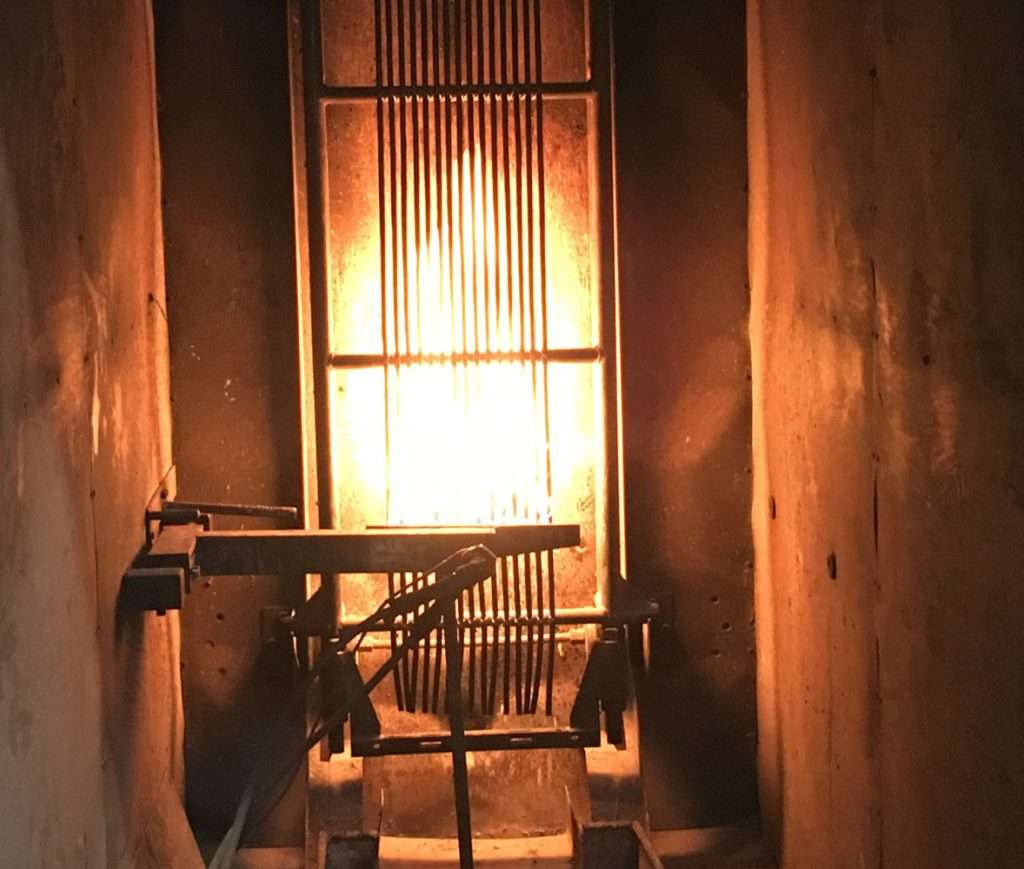

Some of the tests are carried out during manufacturing, including cable concentricity, insulation properties, overall dimension and voltage testing. In other occasions, cable samples are intentionally pushed to the limits of their performance beyond normal operating conditions: in our testing laboratories we simulate and verify cable tensile strength and elongation, continuous flexing, abrasion & impact resistance, aging simulation, exposure to extremely high or cold temperatures, UV stability, flame, fire, smoke, droplets and acid gasses behavior, just to name a few.

RELIABILITY AND PERFORMANCE

With Top Cable expertise and state-of-the-art cable testing laboratories, we can help you ensure the reliability and performance of the cables we supply for your critical infrastructure.

We deliver more than 50 different tests covering the entire spectrum of our cable range.

100% of our electrical cable drums are tested throughout the entire development and production process.

Samples of electrical cables are subject to aging simulation to predict how cables are likely to perform over time.

During the manufacturing process of an electrical cable, highly trained personnel test that the cable design standards are met.

As the first company to achieve Cca classification, Top Cable has established itself as a benchmark for compliance with CPR B2ca and Cca fire cable regulations.

We also monitor and control the origin of our raw materials, working only with verified suppliers who guarantee the quality of our cables.

We use various equipment and specialized personnel to conduct rigorous MV quality tests to ensure our Medium Voltage cables meet your most demanding requirements.

SENT YOUR CABLE REQUEST FOR QUOTE

Our dedicated team of experts will take the time to understand your specific requirements, whether you need a small batch of custom cables or a large-scale solution for an industrial project. This attention to detail ensures that the quote you receive is tailored to your needs, helping you make informed decisions and avoid costly delays.

Simply contact Top Cable today and ask for a no-obligation cable request for quote.