2026 Best Print Inspection Systems What to Look For?

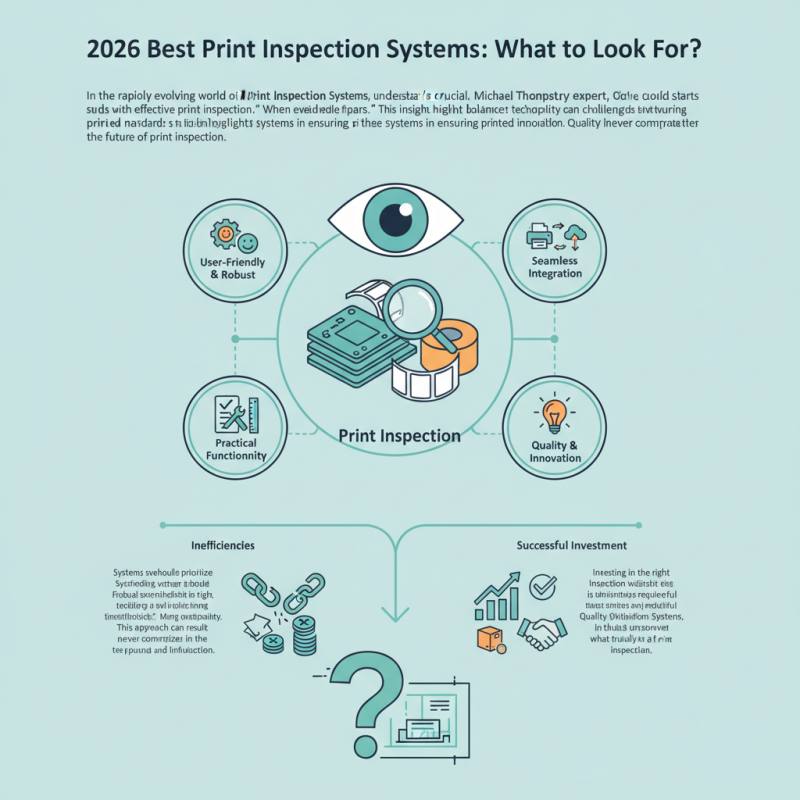

In the rapidly evolving world of Print Inspection Systems, understanding the key features is crucial. Michael Thompson, an industry expert, states, “Quality control starts and ends with effective print inspection.” This insight highlights the importance of these systems in ensuring printed materials meet high standards.

When evaluating Print Inspection Systems, various factors come into play. Systems should be user-friendly yet robust. Finding the right balance between technology and simplicity can be challenging. Additionally, integration with existing workflows is often overlooked, leading to disruptions in production.

Many companies prioritize flashy features over practical functionality. This approach can result in wasted resources and inefficiencies. Investing in the right Print Inspection Systems requires careful consideration. Quality should never be compromised in the pursuit of innovation. Through this exploration, we aim to uncover what truly matters in the future of print inspection.

Key Features of Print Inspection Systems for 2026

When choosing a print inspection system in 2026, consider key features that enhance performance. A high-resolution camera is crucial. It detects imperfections with precision. Look for systems that offer real-time inspection capabilities. Fast detection helps maintain production quality.

Tips: Always test the system in your production environment. Variations in materials can affect performance. Regular updates to software can improve accuracy.

Another important feature is user-friendly software. Operators should easily navigate the interface. Complex systems may slow down workflow. Automated reporting tools are also valuable. They help track issues over time.

Tip: Involve your team in the selection process. Their insights can identify potential challenges with new systems. Don't overlook the importance of customer support. A responsive service team can solve problems quickly.

Emphasizing these components can lead to better overall printing quality. Those who prioritize these features often see fewer defects. Reflect on your current processes and consider how improvements can be made.

Advancements in Print Inspection Technology to Consider

In the evolving landscape of print inspection technology, several advancements are shaping the industry. Automated systems are now more sophisticated, enhancing their ability to detect defects. Real-time quality checking is becoming a standard feature. These systems can flag errors instantly, reducing wastage and ensuring higher quality output. The integration of artificial intelligence is another exciting development. AI can learn from past data, improving accuracy over time.

The importance of user-friendly interfaces cannot be overstated. Many operators struggle with complicated systems. A clear, intuitive design can make a significant difference. Even with advanced technology, the human element remains crucial. Training staff effectively on new systems is often overlooked. Poor training can lead to mistakes and inefficiencies, negating technological benefits.

Furthermore, flexibility in print inspection systems is essential. Different projects require different approaches. A one-size-fits-all solution may not work for everyone. Companies should consider scalability as their needs evolve. Investing in adaptable technology could mean the difference between success and failure. Balancing innovation with usability is vital for achieving optimal results.

2026 Best Print Inspection Systems: What to Look For?

| Feature | Description | Importance | Advancements |

|---|---|---|---|

| Resolution | High resolution allows for detailed inspection of print quality. | Critical for identifying defects. | Advancements in sensor technology improve resolution capabilities. |

| Speed | Faster inspection speeds ensure high throughput in production. | Essential for maintaining production efficiency. | Real-time processing allows quicker inspections. |

| Automation | Automation reduces manual errors and labor costs. | Highly valuable for scaling operations. | Integration with AI for enhanced decision-making. |

| User Interface | Intuitive UI facilitates easy operation and training. | Important for reducing training time. | Modern interfaces incorporate touchscreens and customizable dashboards. |

| Data Management | Robust data management helps in tracking inspections and quality trends. | Crucial for long-term quality improvement. | Cloud solutions offer enhanced data storage and access. |

Criteria for Evaluating Print Inspection Systems

When evaluating print inspection systems, the first criterion to consider is image quality. A high-resolution camera is essential. It ensures that even the smallest defects are detected. Look for systems that can capture fine details. This can make a big difference in quality control. The ability to detect colors accurately is also crucial. Misprints in colors can lead to significant issues.

Next, think about ease of use. A complicated interface can slow down production. Intuitive software saves time. Operators should be able to understand it quickly. Training should not take weeks. Furthermore, consider the speed of inspection. A system should keep up with production rates. Slower systems can lead to bottlenecks.

Lastly, adaptability is vital. Different print jobs require different settings. Systems that can be easily adjusted are more efficient. Sometimes, models claim to be versatile but fall short. It’s essential to test them under real conditions. Regular updates are also necessary to stay relevant. Being stuck with outdated technology can hinder progress.

2026 Best Print Inspection Systems Evaluation Criteria

Best Practices for Implementing Print Inspection Solutions

When implementing print inspection solutions, defining clear goals is essential. Understand what you want to achieve. This could be reducing defects or improving quality consistency. Without clear targets, you might miss key issues.

Training staff is another crucial aspect. Employees need to understand how to use the systems effectively. Yet, many companies overlook this. A lack of proper training can lead to underutilization of the technology. This is a common mistake that hinders efficiency.

Regular maintenance is vital for longevity. It's easy to forget about upkeep. However, neglect can lead to reduced accuracy over time. Schedule routine checks and ensure everything functions correctly. This can save money in the long run.

Top Brands and Models to Explore in 2026

In 2026, print inspection systems are crucial for quality control. The industry is evolving rapidly. Top brands focus on automation and precision. According to recent reports, up to 80% of manufacturers rely on these systems to minimize defects. This indicates a strong trend toward enhanced quality assurance.

When exploring the best models, features matter. Look for those with high-resolution imaging. Systems that offer real-time analytics prove beneficial. Data shows that companies using advanced inspection tools reduce errors by 30%. However, some models may struggle in low-light conditions. This can be a significant drawback, causing delays if not addressed.

Investing in the right system requires careful consideration. Opt for solutions that provide user-friendly interfaces. Complexity can lead to underutilization. A significant portion of operators feels overwhelmed by intricate systems. Hence, simplicity in design can improve performance and adoption. Always be prepared to reassess the effectiveness of your choice in the dynamic market.