Ultimate Checklist for Global Buyers to Choose the Right Electrical Power Cable

In the rapidly evolving energy landscape, the selection of the right Electrical Power Cable has become paramount for global buyers aiming to enhance efficiency and sustainability. According to a recent market report by Allied Market Research, the global electrical cable market is projected to reach $275 billion by 2027, driven by significant investments in renewable energy and infrastructural development. As industries increasingly pivot towards renewable resources, various alternatives emerge, each offering unique advantages in terms of conductivity, durability, and environmental impact. Buyers must navigate a myriad of options, from traditional copper and aluminum cables to newer innovations like high-temperature superconductors and recyclable materials. Such considerations not only affect operational performance but also align with the growing demand for greener electrical solutions, making it essential for stakeholders to have a well-informed checklist at their disposal when choosing the appropriate Electrical Power Cable for their specific applications.

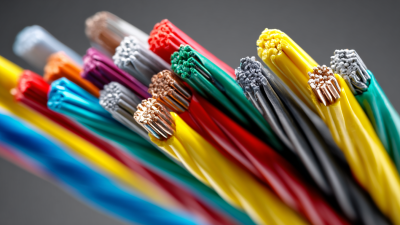

Understanding Different Types of Electrical Power Cables for Global Buyers

When it comes to selecting electrical power cables, global buyers must navigate a multitude of options, each designed for specific applications and environments. Understanding the different types of electrical power cables is crucial for making informed purchasing decisions. For instance, low-voltage cables are ideal for general wiring tasks, while medium-voltage options are suitable for industrial applications. High-voltage cables, on the other hand, are employed in power transmission systems, ensuring efficient delivery of electricity over vast distances.

Additionally, buyers should consider the specific materials used in cable construction, as this significantly impacts performance and durability. Copper and aluminum are the most common conductors, with copper offering higher conductivity and aluminum being lighter and more cost-effective. Insulation materials, such as PVC or XLPE (cross-linked polyethylene), also play a critical role in safeguarding cables from environmental hazards. By understanding these differences, global buyers can select the appropriate electrical power cables that align with their project requirements and compliance standards, ensuring safety and efficiency throughout their operations.

Key Selection Criteria for Choosing the Right Electrical Power Cable

When selecting the right electrical power cable, several key criteria should guide your decision-making process. First and foremost, understanding the application requirements is crucial. Consider the environment where the cable will be installed—whether it's indoors or outdoors, in industrial settings, or residential areas. Each scenario demands specific cable types that can withstand varying conditions, such as temperature fluctuations, moisture, and potential chemical exposure.

Another vital factor to consider is the cable's electrical specifications. This includes voltage rating, current-carrying capacity, and the overall resistance of the cable. Ensure that the chosen cable meets or exceeds the necessary safety standards and regulations for your region. Additionally, take into account the length of the cable run, as longer distances may require thicker cables to minimize voltage drop and ensure efficient power delivery. By carefully assessing these criteria, global buyers can make informed choices that guarantee performance and safety in their electrical applications.

Comparative Analysis of Copper vs. Aluminum Power Cables

When it comes to selecting the right electrical power cable, one of the most critical decisions is choosing between copper and aluminum conductors. Copper cables are well-known for their superior conductivity and durability, which enables them to carry more current and withstand harsh conditions without significant deterioration. They also tend to have a longer lifespan, often translating to lower long-term costs. However, copper is generally more expensive, which can be a drawback for budget-conscious projects.

On the other hand, aluminum cables present an attractive alternative, especially for large-scale applications. While they conduct electricity less efficiently than copper, aluminum is much lighter, making installation easier and less labor-intensive. Additionally, the lower material cost of aluminum can significantly reduce upfront expenses. However, buyers must be aware that aluminum requires careful handling to prevent issues related to corrosion and expansion, which may necessitate additional maintenance over time. Ultimately, the choice between copper and aluminum will depend on specific project needs, budget constraints, and local environmental factors.

Common Applications and Uses of Various Electrical Power Cable Types

When selecting the right electrical power cable, understanding the common applications and uses of various types is crucial for ensuring safety and efficiency. For residential wiring, non-metallic sheathed cables are commonly used due to their flexibility and ease of installation. They are ideal for indoor applications and can support multiple circuits, making them a go-to choice for lighting and outlet connections in homes.

In industrial settings, armored cables are preferred for their robust protection against physical damage and environmental factors. These cables are often used in situations where high voltage and heavy machinery are present, such as manufacturing plants. Additionally, specialized cables like flexible cords are essential for portable equipment and temporary power supply needs, providing the necessary durability and versatility to withstand frequent movement. Understanding these distinctions helps global buyers make informed decisions tailored to their specific operational requirements.

Regulatory Standards and Certifications for Global Electrical Power Cables

When selecting electrical power cables for global use, understanding the relevant regulatory standards and certifications is crucial. Each region has its own governing bodies that establish specific guidelines to ensure safety and reliability. For instance, in the United States, the National Electrical Manufacturers Association (NEMA) and Underwriters Laboratories (UL) set rigorous standards that cables must meet. Similarly, in Europe, compliance with the International Electrotechnical Commission (IEC) standards and obtaining the CE marking are essential for market entry. These regulations ensure that the cables can withstand environmental stresses and function safely under various operating conditions.

Moreover, certifications often indicate a product's quality and performance characteristics. For example, cables certified by the American National Standards Institute (ANSI) signal adherence to high performance standards. Additionally, international certifications, such as ISO 9001 for quality management systems, can enhance a manufacturer's credibility and facilitate smoother cross-border trade. Buyers should thoroughly check if the cables they consider meet local and international standards before making a purchase, as this not only ensures operational efficiency but also protects against liability and reinforces trust in supplier capabilities.

Ultimate Checklist for Global Buyers to Choose the Right Electrical Power Cable

| Regulatory Standard | Region | Certification | Cable Type | Voltage Rating | Temperature Rating |

|---|---|---|---|---|---|

| IEC 60227 | Global | CE | PVC Insulated | 0.6/1kV | 70°C |

| UL 44 | North America | UL Listed | Rubber Insulated | 600V | 90°C |

| BS 7870 | UK | BSI Kitemark | XLPE Insulated | 0.6/1kV | 90°C |

| NFC 32-201 | France | NF | LSOH | 0.6/1kV | 70°C |

| AS/NZS 5000.1 | Australia/New Zealand | SAA | H07RN-F | 450/750V | 90°C |

Related Posts

-

How to Choose the Best Power Cable for Your Global Sourcing Needs

-

Exploring Innovative Alternatives to Best Power Cable Electrical for Sustainable Solutions

-

Empowering the World with China's Leading Electrical Power Cable Innovations

-

Maximizing Value with Best Top Cable Solar After Sale Service and Maintenance Cost Advantages

-

Understanding Import Export Certifications for Best Rubber Flexible Cable in the Global Market

-

Futureproofing Your Supply Chain with Best Cable Electric Wire Trends for 2025