How to Choose the Right Voltage Cable for Your Industrial Needs

In today's industrial landscape, selecting the appropriate Voltage Cable is crucial for ensuring operational efficiency and safety. The global market for industrial cabling is projected to reach $150 billion by 2025, driven by increasing investments in infrastructure and rapid technological advancements. As industries shift towards smarter and more energy-efficient systems, understanding the specifications and applications of different types of Voltage Cables becomes essential. Each type serves distinct purposes, from power transmission in manufacturing plants to data transfer in automation systems. According to a recent report by the International Energy Agency, improper cable selection can lead to energy losses of up to 30%, emphasizing the necessity for informed choices. This blog aims to guide you through the process of choosing the right Voltage Cable tailored to your specific industrial requirements, ensuring both reliability and cost-effectiveness.

Understanding Voltage Ratings and Their Impact on Industrial Applications

When selecting the appropriate voltage cable for industrial applications, understanding voltage ratings is crucial. Voltage ratings indicate the maximum voltage that a cable can safely handle, influencing both the performance and safety of electrical installations. According to a report by the International Electrotechnical Commission (IEC), improper voltage ratings can lead to insulation breakdown, which is a common cause of electrical failures in industrial settings. For instance, the IEC highlights that cables used in environments with voltages exceeding their rating can experience catastrophic failures, affecting equipment and productivity.

Moreover, the National Electrical Manufacturers Association (NEMA) underscores that specific industries have standardized voltage requirements. For example, manufacturing facilities often operate at 480V, which necessitates the use of cables rated for such voltages to ensure optimal performance. In fact, a study by the Electrical Safety Foundation International (ESFI) revealed that over 25% of industrial electrical accidents are linked to inadequate understanding of voltage ratings. This emphasizes the importance of choosing cables that not only meet the operational voltage but are also compliant with industry standards to mitigate risks and enhance efficiency in industrial applications.

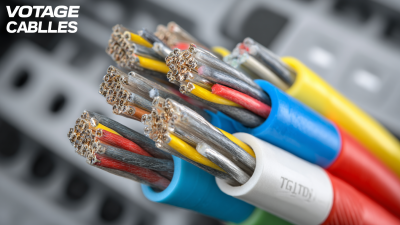

Types of Voltage Cables: An Overview of Options Available

When selecting the right voltage cable for your industrial applications, it's essential to understand the various types of cables available. First, there are low voltage cables, which typically operate at voltages up to 1,000 volts. These cables are commonly used for power distribution in factories, commercial buildings, and residential applications. They come in different materials, such as copper or aluminum, and can be further categorized into single-core and multi-core options, each suited for specific tasks.

On the other hand, high voltage cables are designed for applications exceeding 1,000 volts and are crucial for transmitting electrical energy over long distances. These cables are usually insulated with materials that can withstand higher temperatures and voltages, such as cross-linked polyethylene (XLPE) or ethylene propylene rubber (EPR). Additionally, flexible cables, which are often used in robotics and other movement-intensive environments, provide the necessary adaptability without sacrificing performance. By understanding these options, you can better assess which type of voltage cable aligns with your specific industrial needs, ensuring both safety and efficiency in your operations.

Voltage Cable Types and Their Applications

Evaluating Cable Materials: Copper vs. Aluminum for Voltage Performance

When selecting the right voltage cable for industrial applications, understanding the materials used in cable production is crucial—particularly the choice between copper and aluminum. Copper cables, due to their superior electrical conductivity, are often preferred in situations where high performance and reliability are paramount. According to recent industry reports, copper boasts approximately 60% more conductivity than aluminum, making it ideal for high-voltage applications. This characteristic allows for decreased energy losses during transmission, which is vital in both traditional and renewable energy infrastructures.

On the other hand, aluminum cables have gained traction due to their lightweight nature and lower cost. Recent analyses show that aluminum can be a more economical choice without significant sacrifices in performance, particularly in large-scale installations such as wind farms and solar plants. The global market for aluminum cables is projected to grow at a CAGR of 5.3% from 2023 to 2028, driven by advancements in renewable energy technologies and a growing emphasis on sustainable practices. As industries strive to align with eco-friendly initiatives, the choice between copper and aluminum increasingly hinges on balancing performance needs with cost-effectiveness and sustainability goals.

Assessing Cable Insulation Types for Maximum Efficiency and Safety

When selecting voltage cables for industrial applications, understanding cable insulation types is crucial for ensuring maximum efficiency and safety. The insulation material plays a significant role in the cable's performance, influencing factors like thermal resistance and environmental durability. According to a report by the International Electrotechnical Commission (IEC), improper insulation can lead to energy losses of up to 15% and increase the risk of electrical faults.

One of the key insulation types to consider is Thermoplastic Elastomer (TPE), which offers high flexibility and resistance to chemicals and abrasion. This makes TPE ideal for environments where cables are frequently moved. In contrast, cross-linked polyethylene (XLPE) insulation has excellent thermal and electrical properties and is designed for high-voltage applications, making it a preferred choice for power distribution.

One of the key insulation types to consider is Thermoplastic Elastomer (TPE), which offers high flexibility and resistance to chemicals and abrasion. This makes TPE ideal for environments where cables are frequently moved. In contrast, cross-linked polyethylene (XLPE) insulation has excellent thermal and electrical properties and is designed for high-voltage applications, making it a preferred choice for power distribution.

Tips: Always verify the operating temperature range of the insulation material, ensuring it can withstand extreme conditions. Additionally, consider the cable's application environment—if it's exposed to moisture or chemicals, select an insulation type that meets those specific challenges. Finally, consult with manufacturers or professionals to ensure compliance with industry standards for safety and efficiency.

Key Factors to Consider When Selecting Voltage Cable Length and Thickness

When selecting the appropriate voltage cable for industrial applications, two critical factors come into play: cable length and thickness. The length of the cable is essential as it directly impacts the voltage drop, which can affect the efficiency of equipment. Longer cables tend to experience more resistance, leading to power loss. Therefore, it's crucial to calculate the required cable length accurately and consider additional length if the installation requires bends or elevation changes to prevent performance issues down the line.

When selecting the appropriate voltage cable for industrial applications, two critical factors come into play: cable length and thickness. The length of the cable is essential as it directly impacts the voltage drop, which can affect the efficiency of equipment. Longer cables tend to experience more resistance, leading to power loss. Therefore, it's crucial to calculate the required cable length accurately and consider additional length if the installation requires bends or elevation changes to prevent performance issues down the line.

Thickness, or gauge, is equally important in ensuring safety and optimal function. Thicker cables can handle higher currents and reduce the risk of overheating. When determining the right thickness, factors such as the current rating, thermal properties, and installation conditions must be evaluated. It's advisable to consult industry standards and guidelines to determine the appropriate gauge for specific applications, ensuring that the cable can operate efficiently without compromising safety thresholds. Balancing these two factors is essential to meet the demands of your industrial setup while minimizing potential risks.

Related Posts

-

Maximizing Performance with Best Low Voltage Cable Strategies for Enhanced Efficiency

-

Unlocking Global Trade with Best Voltage Cables Understanding Import Export Certifications for Compliance

-

Empowering Global Connections with China's Finest Voltage Cables

-

Top Strategies for Sourcing High-Quality Solar Electric Solutions Globally

-

Navigating Industry Production Standards Challenges for Best Medium Voltage Cable

-

Understanding Import Export Certifications for Best Rubber Flexible Cable in the Global Market