Ultimate Comparison: Top 5 Best Medium Voltage Cables for Your Industrial Needs

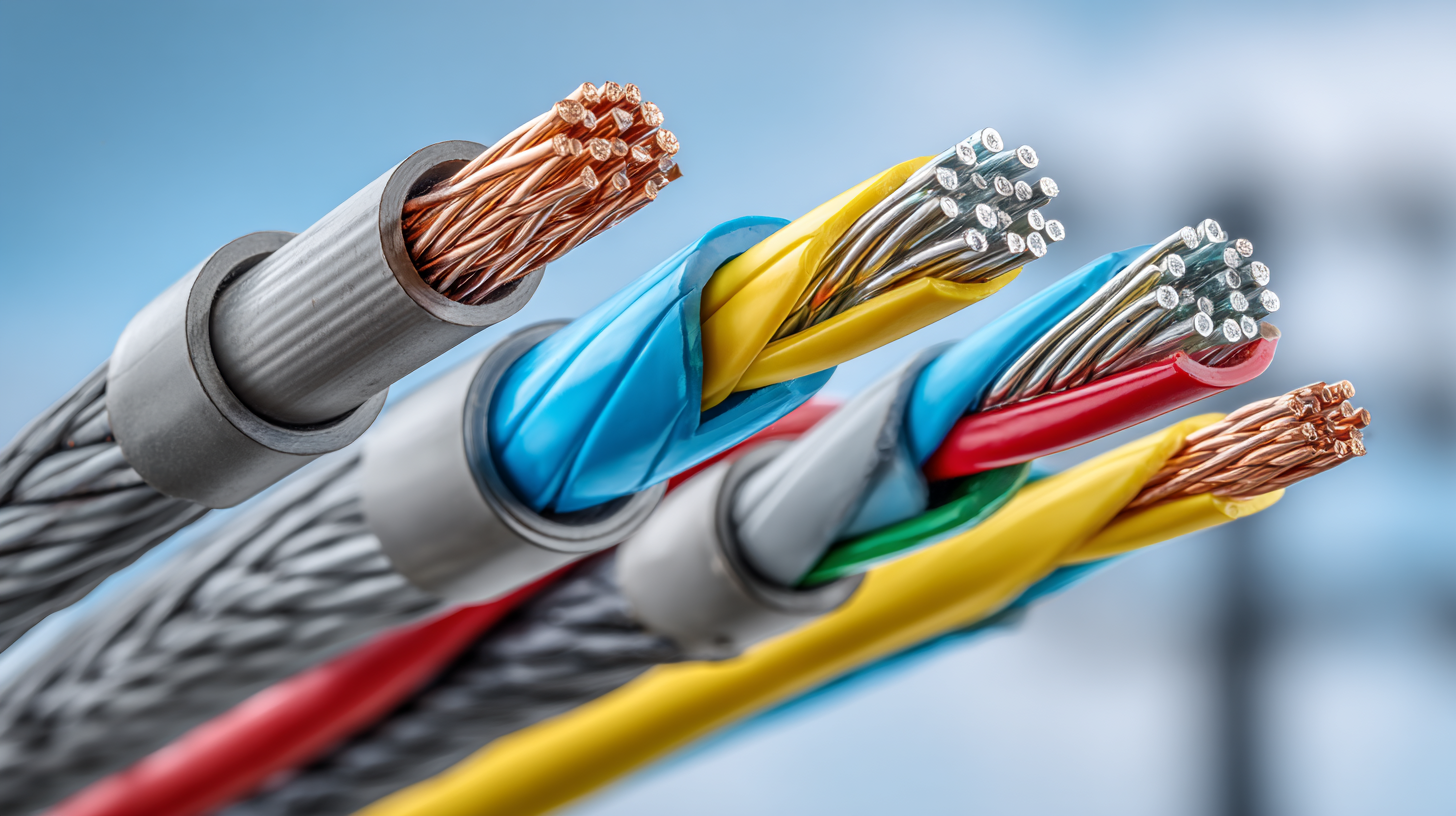

When it comes to powering industrial operations, selecting the right Medium Voltage Cable is critical for ensuring safety, efficiency, and reliability. Medium voltage cables serve as the backbone of electrical distribution systems, providing the necessary connection between power sources and equipment. However, with the myriad of options available on the market, choosing the best cable for your specific needs can be a daunting task. In this ultimate comparison, we will delve into the top 5 best medium voltage cables that cater to various industrial requirements, exploring their distinct features, advantages, and ideal applications. Whether you're involved in manufacturing, energy production, or any other industrial sector, this guide aims to equip you with the knowledge needed to make an informed decision about your medium voltage cable investments.

Key Innovations in Medium Voltage Cables for Industrial Applications in 2025

As we advance into 2025, medium voltage cables are witnessing significant innovations designed to meet the evolving demands of industrial applications. One of the most notable trends is the integration of enhanced materials that improve durability and efficiency. For instance, the use of cross-linked polyethylene (XLPE) insulation has become increasingly prevalent, offering superior thermal resistance and reduced electrical losses. This advancement not only prolongs the lifespan of cables but also ensures more reliable performance in harsh industrial environments.

Additionally, advancements in production technology have led to the development of cables that are both lighter and more flexible without compromising on strength. These innovations facilitate easier installation and maintenance, which is crucial for minimizing downtime in industrial settings. Furthermore, the incorporation of smart technology within medium voltage cables is gaining traction, allowing for real-time monitoring and predictive maintenance. This smart capability enhances safety and operational efficiency, addressing many of the challenges faced by industrial operators today. The future of medium voltage cables looks promising, driving greater productivity and reliability in industrial operations.

Understanding the Different Types of Medium Voltage Cables and Their Advantages

When selecting medium voltage cables for industrial applications, it’s essential to understand the different types available, as each offers unique advantages tailored to specific operational needs. Generally, medium voltage cables, typically rated between 1 kV and 35 kV, are categorized into various types such as cross-linked polyethylene (XLPE), ethylene propylene rubber (EPR), and paper insulated cables.

XLPE cables, known for their excellent thermal stability and resistance to environmental stress, are ideal for outdoor installations. EPR cables, on the other hand, provide superior flexibility and durability, making them favorable for applications that require frequent movement or bending.

XLPE cables, known for their excellent thermal stability and resistance to environmental stress, are ideal for outdoor installations. EPR cables, on the other hand, provide superior flexibility and durability, making them favorable for applications that require frequent movement or bending.

Tip: Always assess the specific environmental conditions of your installation site before making a decision. For example, if your cables will be exposed to high moisture levels, consider selecting cables with a higher level of insulation and water resistance to ensure longevity.

Another crucial aspect to consider is the cable’s current-carrying capacity. Selecting a cable that matches or exceeds the required current is vital to avoid overheating and potential electrical failures. A careful assessment of both power requirements and load conditions can help in choosing the optimum cable type.

Tip: Conduct regular maintenance checks on your medium voltage cables. Over time, external factors like heat, moisture, and physical wear can impact their performance, so ensuring they are monitored and maintained can prevent costly downtime in your operations.

Impact of Technological Advancements on Cable Efficiency and Longevity

The rapid pace of technological advancements in the electrical industry has significantly impacted the efficiency and longevity of medium voltage cables. These developments have revolutionized the way cables are manufactured, resulting in materials that boast enhanced conductivity, durability, and resistance to environmental factors. For instance, innovations in insulation materials and shielding practices have not only improved performance but also extended the lifespan of cables, reducing the frequency and cost of replacements in industrial settings.

Moreover, the implementation of smart technologies in cable management systems has facilitated real-time monitoring and diagnostics. This capability allows for predictive maintenance, ensuring that potential issues are identified before they lead to failures. As a result, industries benefit from increased reliability and reduced downtime, which are essential in today’s competitive landscape.

Overall, these advancements illustrate a significant shift towards more efficient, manageable, and longer-lasting medium voltage cables, tailored to meet the demanding needs of various industrial applications.

Market Trends and Demand for Medium Voltage Solutions in Industrial Sectors

The demand for medium voltage solutions in industrial sectors continues to grow significantly, driven by advancements in technology and the increasing need for reliable power distribution. The Medium Voltage Drive market is particularly noteworthy, with projections indicating it will expand at a CAGR exceeding 6.1% from 2025 to 2034. This growth is attributed to the rising efficiency requirements across various industries and the urgency to enhance energy management systems.

When selecting medium voltage cables, it’s essential to consider factors like the cable's insulation type, conductor material, and the environmental conditions in which they will operate.

Tips: Ensure that the cables are compliant with safety standards and have the appropriate voltage and current ratings. Regular inspections and maintenance can also prolong the lifespan of these cables, minimizing downtime in industrial settings. Furthermore, staying updated on market trends can help you make informed decisions that align with your operational needs and budget constraints.

As industries increasingly prioritize energy efficiency and sustainability, the medium voltage sector is positioned for robust growth, underscoring the necessity for informed investments in high-quality solutions.

Cost-Benefit Analysis of Upgrading to Modern Medium Voltage Cable Technologies

Upgrading to modern medium voltage cables can significantly impact both operational efficiency and cost management in industrial settings. According to a report by the International Energy Agency (IEA), transitioning to high-quality medium voltage cables can reduce energy losses by up to 30%. This reduction directly translates to lower electricity bills and enhanced system reliability, making the investment worthwhile. Furthermore, modern cables are designed to withstand harsher operating conditions, which can potentially extend the replacement cycle, as indicated by the IEC 60076-1 standard that emphasizes the longevity and durability of advanced cable technologies.

From a cost-benefit perspective, the initial investment in modern medium voltage cables may be higher, but the long-term savings can be substantial. A study conducted by the Electrical Power Research Institute (EPRI) reported that industries transitioning to updated cable technology saw operational cost reductions of approximately 15% over five years. This is largely due to decreased maintenance needs and improved energy efficiency. Moreover, as regulations around energy consumption tighten, investing in modern cable solutions not only aids compliance but also positions companies as leaders in sustainability efforts, garnering positive public perception and potentially unlocking new market prospects.