At Top Cable we believe that the installation of industrial switchboards is a task that…

Secure installation of a cable

The first step to ensure the safe installation of a cable is to have it installed by a qualified and authorised installer, with the optimum knowledge to carry out the work. Having the relevant qualification, it is the installer’s responsibility to know the regulations in force in each territory in which the installation of a cable is carried out. A qualified person will have the knowledge to be able to make a correct prior selection of the cable, thus minimising the risks of a malfunction.

LAYOUT INSTALLATION OF A CABLE

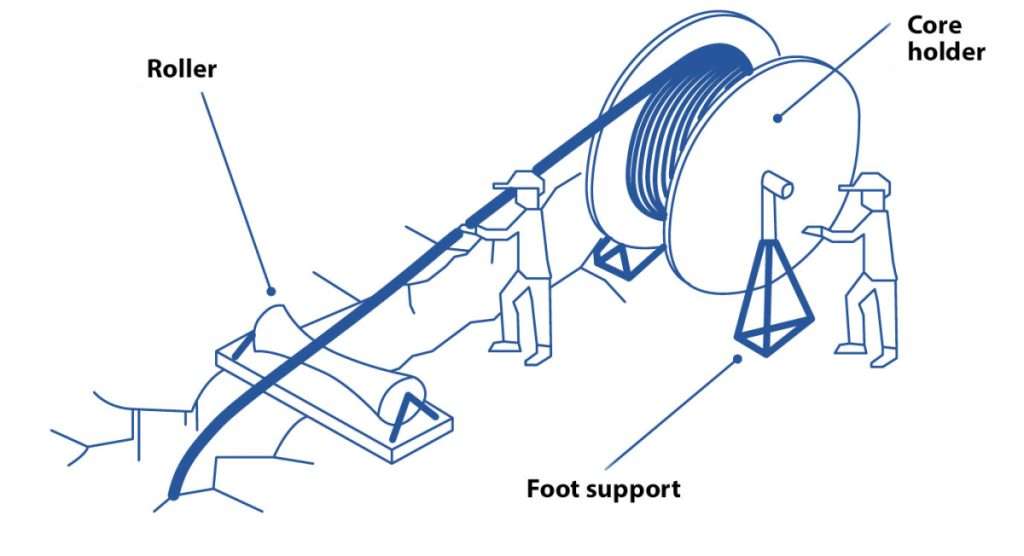

One of the most important factors to consider is the cable routing during installation. On the one hand, the distance the cable will need to travel, as well as the complexity of the cable. The use of a roller when installing the cable, with a suitable width and surface, avoids external aggressions that may damage the cable sheath. A small reduction in the permitted bending radius may be considered, in which case the minimum temperature of the cable must be at least 30ºC and the bending must be carried out using a pre-formed roller.

For correct winding and unwinding of the cable, the reel must be elevated by 10 – 15 cm. The reel must be in a vertical position, as a horizontal position can seriously damage the cable due to the single or double twist that can be generated from the cable exit on the reel to the trench.

INSTALLATION OF A CABLE OUTSIDE

There are different environmental aspects that must be taken into account when installing an electrical cable. On the one hand, the presence of water or humidity must be assessed. Any damage to the outer sheath of the cable during installation may cause the cable to malfunction due to the access of water or humidity inside. The cable end protections must not be removed until the installation has been completed. In case of earlier removal and detection of damage to the cable, it is recommended to inspect the first metre of cable and, if necessary, cut it off and discard it.

The temperature to which the cable is going to be exposed is another element to be taken into account, and it is essential to be informed about the minimum/maximum service and installation and/or handling temperature. This information is easily accessible through the technical data sheet of the cable.

A third important environmental aspect to take into account is the protection of the cable against fire, and it is necessary to verify that the cable complies with current legislation and, if necessary, to validate the CPR regulation rating it complies with. AS or AS+ rated cables are the safest in case of fire, facilitating evacuation tasks and protecting material goods.

TENSILE STRENGTH

The configuration of a rope installation and the mechanism selected to carry it out determine the applicable pulling force on the job. It is very important not to exceed it because doing so may damage the cable, either by breaking it or by minimising its service life to an optimum level.

SUPPORTED INSTALLATION

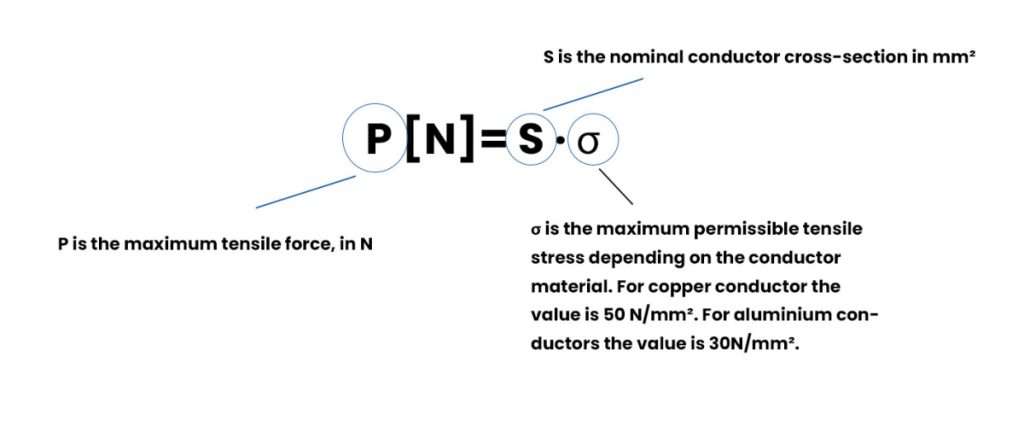

In the case of a supported cable installation (where the weight of the cable itself is in direct or indirect contact with the ground or subsoil over the entire length of the cable), the maximum tensile force on the conductor is calculated using this formula.

The maximum tensile strength takes into account a maximum permissible conductor elongation of 0.2%. In case of a multicore cable, the sum of all nominal conductor cross-sections is taken into account.

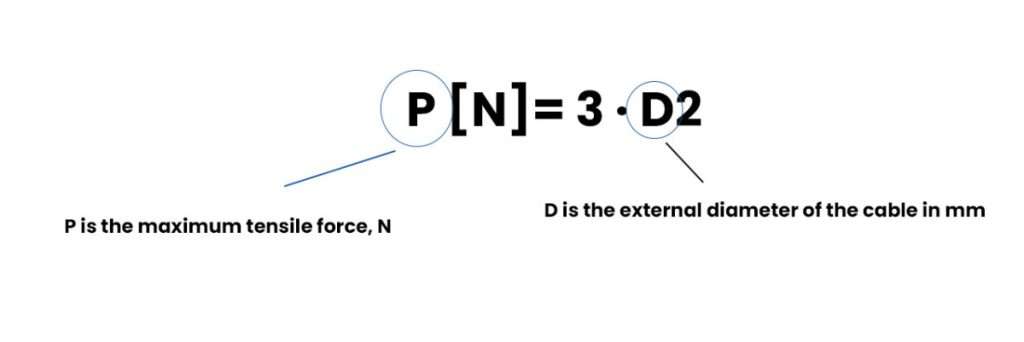

The tensile force can also be applied by means of a friction mechanism acting on the outer sheath. In this case, the maximum tensile force is calculated with this formula.

It must be verified that the tensile force on the outer sheath does not exceed the force calculated with the conductor cross-section. However, at Top Cable we do not recommend this method, as the tensile stress caused on the sheath material may, depending on the environmental conditions, lead to subsequent shrinkage of the sheath, causing future problems.

For single-core cables, we recommend that the total value of the tensile force should not exceed 2.5 times the maximum force of a single cable. In the case of cables laid in parallel the total tensile force should not exceed N-1 times the maximum value for a single core cable, where N is the number of parallel cables laid at the same time.

SELF-SUPPORTING INSTALLATION

Another type of installation is self-supporting (cables are installed in walls and ceilings, a few metres above the floor), where stress concentration in the cables must be avoided by placing them in natural positions before fixing them.

In case of spaced laying of single-core cables, plastic cable ties can be used to hold the cable (they can also be made of steel as long as there is no magnetic circuit on the single-core cable). It is important not to put excessive pressure on the cable with the cable tie so that the cable can undergo longitudinal and transverse expansion and contraction caused by thermal effects without damage.

OTHER RECOMMENDATIONS FOR THE INSTALLATION OF A CABLE

Finally, in order to correctly complete the installation of an electrical cable, we recommend that the information provided in the technical data sheet regarding the minimum bending radius, vibrations, chemical agents, impacts and other environmental effects be taken into account

For any questions you may have during the process, do not hesitate to contact our technical team.